Product quality and process control for us means having the best equipment and the right resources to meet customer requirements.

Our in-house quality assurance team maintain close communications with customers to ensure that customer requests are clearly understood and completely achieved.

Our laboratory uses high precision instrumentation to perform metallographic tests on raw material and finished products.

We meet all the quality and technical analysis requirements requested by our customers.

We use all the equipment necessary to perform metallographic tests on raw material and finished products.

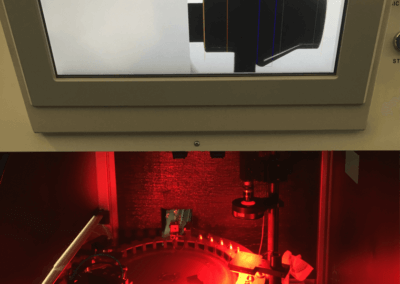

We also use generic instruments in order to verify our production flow and those coming from high-precision laboratory (such as 3D SCAN machine – CNC profilometer – fiber optic profile projectors, millesimal altimeters).

To guarantee 100% quality, we have two sorting machines with high resolution optical vision for dimensional and / or aesthetic controls.